Help for homeless sea creatures

Precast concrete units rebuild the aquatic environment

Human recreational activity,

pollution and natural disasters have destroyed many natural coral reef systems in the

world's oceans. Where natural reefs can't rebuild themselves quickly enough to prevent

damage to beaches and fish populations, one environmentally sound solution is to build

artificial reefs with Reef Balls, dome-shaped hollow concrete balls with holes in them

that mimic natural coral reefs.

Some ready-mixed and precast concrete producers have gained goodwill

and an outlet for waste concrete by becoming, or partnering with, Reef-Ball licensees.

Tim Guscette, plant manager at Southdown Inc.'s Concrete Products

Division in Sarasota, Fla. (formerly Florida Mining and Materials), notes that it's an

excellent way to put to good use ends of loads and rejected loads the company would

otherwise have to dispose of. This is because producers like Guscette can cast Reef Balls,

somewhat rough and imperfect by design, with almost any waste concrete, as long as it's

adjusted with the required admixtures and remixed. "It's a great public relations

thing for us to do, as well as a positive thing for the environment," says Guscette.

Beach balls to Reef Balls

Often, artificial reefs are sunken ships, tires, old train cars or crumbled bridges. Todd

Barber, now president of the Reef Ball Development Group Ltd. (RBDG), a volunteer

environmental organization, got tired of scuba diving around these trash heaps. Wishing to

see more long-lasting, environmentally friendly reefs, he came up with the idea for Reef

Balls.

Barber and his buddies began by trying to cover beach balls with

chicken wire and concrete with the plan of floating them out to sea, popping the balls and

letting the shells sink to the bottom. This is essentially how the Reef Ball works.

A Reef Ball is made by placing concrete into a fiberglass mold that

contains a central inflatable buoy surrounded by inflatable balls of various sizes around

which concrete is placed, forming the holes. Though the basic shape is uniform, no two

Reef Balls are identical because the holes are placed and sized manually on each form. The

internal buoy can be left in place to provide flotation for towing the ball out to sea by

boat, then deflated slowly to allow a controlled descent for precise placement by divers.

This placement method makes repairs to existing natural reefs possible. It's also possible

to deploy Reef Balls by less precise methods such as dumping them off a barge, dropping

them from a crane and even flying them out to sea by helicopter.

Reef Balls represent only one of the reef-building products available.

Pallet Balls, Bay Balls, Lo-Pro Balls and Oyster Balls offer variations on the size and

shape. Miniature 6-inch model Reef Balls are also available and make good reefs in

saltwater aquariums.

All

photos courtesy Reef Ball Development Group Ltd.

All

photos courtesy Reef Ball Development Group Ltd.

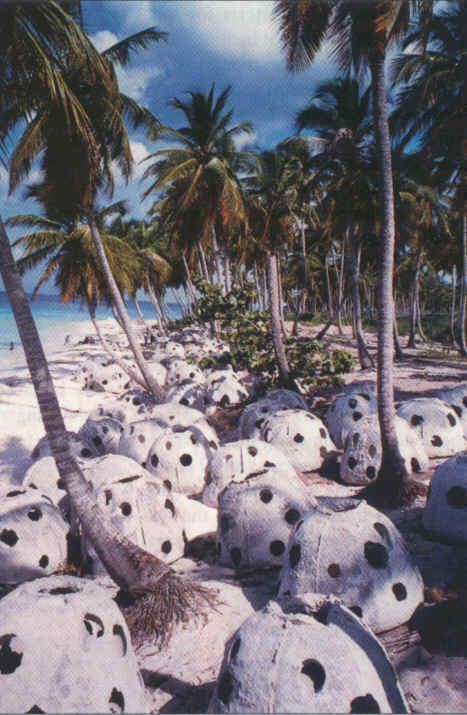

Reef Balls awaiting deployment far a beach

restoration project in the Dominican Republic.

Why concrete?

The use of concrete to construct artificial reefs offers several

advantages. Reef Balls are heavy enough to be stable on the sea floor (they have withstood

hurricanes without moving) yet provide multiple entrances and internal cavities for

shelter. Concrete contains no toxins and the surface of the balls can be rough and

textured to enhance marine growth. Reef Balls carefully designed for the local environment

should last hundreds of years.

The concrete mix design for Reef Balls is tailored for each location

and application. Design criteria for saltwater deployment might include:

• 4500-psi compressive strength

• Type II Portland cement

•Microsilica ( 9% to 10% of the cement volume)

• 7- to 9-inch slump obtained with a high-range water-reducing admixture

(superplasticizer)

• Sugar water surface retarder on mold surfaces

• 4% air entrainment

• Polypropylene fibers

The microsilica helps to create highstrength, abrasion-resistant

concrete with low permeability. Adding microsilica also lowers the initial pH of the

concrete, promoting the growth of desired marine life such as larval corals. It reacts

with the hydration byproduct, calcium hydroxide, to reduce the surface pH from around 12

for normal concrete to one closer to that of natural sea water. Although this reduction

would happen normally under water over three to six months, the initially high pH would

kill some marine species and allow less-desirable resistant species such as barnacles to

take over.

The superplasticizer makes the concrete fluid enough to flow around all

the inflated objects. The producer sprays sugar water onto the mold surfaces before

casting to retard surface setting. This keeps the outside half inch of the concrete from

setting; the producer can then expose the aggregate by rinsing the surface with a hose.

The resulting uneven surface texture encourages the growth of algae, barnacles and coral.

An air-entraining agent may also be used for its surface texture

benefits. It creates tiny pockets in the concrete that pit the Reef Ball's surface,

offering miniature marine organisms places to easily attach themselves.

Reef Balls normally contain no reinforcing steel because iron is

biologically active, serving as a nutrient for algae, which outgrows the more desirable

hard corals. When rebar is necessary, a calcium nitrite-based corrosion inhibitor must be

used. The producer may use polypropylene

fibers to reduce microcracks that can occur in molds with inflatable parts in hot weather

or where the mold temperature is uneven (as when the sun shines on one side).

While most Reef Balls are used in saltwater applications, they are

occasionally used in fresh water over sandy areas to provide a place for fish to spawn.

For freshwater applications, a standard concrete mix with only the superplasticizer added

is suitable. The microsilica, entrained air and surface retarder are not necessary.

Reef Ball molds and demolding of a Reef Ball reveals its

Swiss-cheese-like holes and internal inflated balloon.

Authorized manufacturers

RBDG sells the molds, provides clients with concrete specifications,

helps clients through the permitting process, and licenses manufacturers who market, make

and transport the balls.

Often, producers work in partnership with RBDG's other authorized firms, providing a place

to build the balls and donating materials while volunteers provide the labor. Barber notes

that while RBDG is always looking for additional licensees, it's essential that interested

parties exhibit a genuine concern for the environment before they will be seriously

considered.

Roman Stone Construction Co. in Bay Shore, NY, now in its 95th year of

precast pipe operations, has also become a licensed Reef Ball manufacturer. General

Manager Tom Montalbine believes concrete is a good choice for reef building.

"Concrete and concrete production in general

could be considered environmentally sound because the raw materials are all natural,"

he says. Montalbine's personal interest in scuba diving gives him an extra reason to

appreciate the work of the RBDG and helped spark his initial interest in Reef Balls.

RBDG uses the royalties it receives from its authorized manufacturers

to help fund the Reef Ball Foundation, a nonprofit group that supplies free molds and

support to other nonprofit and research groups who wish to study or help create Reef Ball

reefs. Reef Balls have been deployed off all U.S. coasts, and international use is

widespread and growing. -M. Wynne Palmer

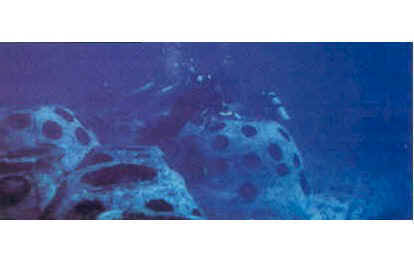

In only one year, significant sponge and soft coral growth

can be realized, as shown on this Bay Ball in the Florida Keys (left). Diver look at

freshly deployed Reef Balls in Cancun, Mexico (right).

Web Link - Extensive information about Reef Balls is also available on the Reef Ball Development Group's Web site: www.reefball.org